Automatic Crane System for Harsh & Heavy Automated Applications

Automatic crane systems - automated overhead crane & automated gantry crane - for automatic handling of steel coil, container stacking,paper rolls & dies.

| Crane type | Automated crane system for harsh and hazardous applications |

| Note | All the automated crane systems are processed to meet the specific applications. |

Category: Hazardous Environment Cranes

Your Trusted Automated Overhead Crane & Automated Gantry Crane Manufacturer & Supplier

Automated Crane for Handling Coils, Paper Rolls, Wastes & Dies

to Improve Your Safety & Efficiency

Automatic crane systems - automated overhead crane & automated gantry crane - for harsh automated applications such as, steel processing, coil stacking, container handling, mold and die handling in stamping plant, and parent roll handing in steel mill, etc.

In the industrial sector, there are certain application environment and material handling works are inherently more dangerous than others, requiring stringent safety measures and high-quality, reliable material handling equipment. Automated overhead cranes and automated gantry cranes , for example, provide a dependable, efficient solution for moving heavy loads while ensuring worker safety in material handling applications.

Why Choose Automated Crane System ?

Oil refining wastes, toxic chemicals, and molten metal all represent major hazards and health risks to workers if not handled properly. Automated cranes are suitable for use in abrasive, toxic, or combustible applications. Automated handling crane systems, on the other hand, allows operators to work from a control room rather than a crane cab, increasing efficiency while reducing the risk of injury.

These automated cranes also relieve operators of the exhaustion that comes with very repetitious handling tasks. The monotony of duty cycles, repetitive lifting and positioning, and continual stacking and storing procedures can all be mechanically managed through automation. This decreases the likelihood of an accident while also improving precision and efficiency.

Automation is changing the way cranes work. In the past, cranes required a lot of manual operation, which often led to mistakes, delays, and even safety issues. Now, automated crane systems are making lifting operations smarter, faster, and safer. Let's take a look at how automation is transforming the crane industry and why it's becoming essential in modern businesses.

Your Trusted Overhead Crane Manufacturer & Supplier

Automated Crane Systems: Smarter, Safer, Faster Lifting

Crane technology has come a long way, especially with the rise of automation. Before, cranes were mostly manually operated, and workers had to be on-site for most tasks. Now, thanks to automation, many cranes can operate with little to no human involvement.

- Automatic Operation: With automated crane systems, cranes can perform lifting tasks on their own, reducing the need for operators to control every movement.

- Efficiency Boost: Automated cranes can work around the clock without breaks, improving overall efficiency.

- Precision: Automation helps cranes operate with high precision, reducing human errors and improving safety.

In industries where heavy lifting is a daily task, this shift to automation is a game-changer.

Key Benefits: Safety, Speed, Efficiency, and Cost Savings

Automated cranes bring several key advantages that manual cranes simply can't match. Here's how:

- Safety: Automation reduces the risk of accidents. Since fewer people are involved in crane operations, the chances of injury from lifting heavy loads or human error are lower. Sensors and real-time monitoring also help detect potential issues before they turn into problems.

- Speed: Automated systems work faster than manual operations. They can lift, move, and position loads more quickly, which increases the overall speed of production. This is especially important in high-demand environments like ports and warehouses.

- Efficiency: Automated cranes can operate continuously without rest, making them much more efficient than traditional cranes. They also use advanced algorithms to optimize lifting patterns, reducing unnecessary movements and saving energy.

- Cost Savings: While the initial investment in automated systems may be higher, the long-term savings are significant. You'll need fewer operators, and there's less downtime for maintenance. Plus, the increased efficiency and speed mean that tasks are completed quicker, leading to higher productivity.

Automatic overhead crane with grab bucket - overhead grab bucket crane for sale

Automati crane with electromagnetic spreader - electromagnetic crane for sale

automatic rail mounted gantry crane and automatic rtg gantry crane - gantry crane for sale

automatic waste handling crane - customized wasste handling crane for sale

automatic coil handling crane - customized coil handling crane for sale

automatic container crane - Customized container crane for sale

Growing Demand: Across Industries Like Ports, Steel Mills, Warehouses, and Logistics Hubs

The demand for automated crane systems is growing fast, and it's happening across multiple industries. Here's a quick breakdown:

- Ports: Ports handle thousands of containers daily, and automation is key to speeding up container handling. Automated gantry cranes, for example, can load and unload ships faster, helping ports meet the growing demand for faster shipping times.

- Steel Mills: Steel mills need reliable and efficient lifting systems to move heavy materials. Automated overhead cranes are perfect for these tasks, ensuring that production runs smoothly without delays caused by human error.

- Warehouses and Logistics Hubs: In warehouses, automated stacking cranes and systems like ASRS (Automated Storage and Retrieval Systems) help organize inventory more efficiently. This allows businesses to save time and space, reducing operational costs.

The growing need for automation in these industries shows how important it is to stay ahead with the latest crane technology.

Automation is the future of crane operations. With clear benefits like safety, speed, efficiency, and cost savings, it's no wonder that more and more industries are adopting these systems. The demand will only continue to rise as businesses strive to meet the challenges of modern-day lifting.

What is an Automated Crane System?

Automated crane systems are designed to reduce the need for human involvement in lifting operations by using advanced technology like sensors, PLCs, and smart software. These systems can operate independently, lifting, moving, and placing loads with little to no manual control. Let's take a closer look at what makes these cranes automated and how they work.

Definition: What Makes a Crane Automated?

An automated crane is one that uses technology to perform lifting and handling tasks autonomously. It does this by relying on sensors to gather data, PLCs to process that information, and automated control systems to execute tasks. This setup allows the crane to function efficiently and accurately without the need for constant human input.

- Sensors: These detect various environmental factors, such as obstacles or load weight, and send data to the control system for decision-making.

- PLCs (Programmable Logic Controllers): These act as the brain of the crane, interpreting the sensor data and making decisions based on pre-programmed instructions.

- Automated Control Systems: These systems process data and send commands to the crane's mechanical components (e.g., motors and brakes) to carry out tasks without human intervention.

- Smart Systems: Integrated AI and machine learning technologies that enhance the crane's performance by allowing it to learn from past tasks and optimize future actions.

Automation Levels: Semi-Automated vs. Fully Automated Cranes

Crane systems can vary in terms of their level of automation. The key difference lies in the amount of human involvement required. While semi-automated cranes still need some operator input, fully automated cranes are designed to run entirely on their own.

- Semi-Automated Cranes: These cranes can perform most of the tasks automatically but may still need a human operator to intervene in certain situations. For instance, a semi-automated crane can transport a load to a specific location, but an operator might need to fine-tune the placement.

- Fully Automated Cranes: These cranes operate with zero human involvement. Once programmed, they can perform all tasks—lifting, moving, and placing—without any manual control. This makes them ideal for continuous, high-volume operations, like container handling at ports.

Traditional vs. Automated Cranes: Key Differences

The main differences between traditional and automated cranes are in their operation and performance. Traditional cranes rely entirely on manual input from operators, while automated cranes use technology to perform many tasks autonomously.

- Human Involvement: Traditional cranes require operators to control all movements, while automated cranes require little or no human intervention.

- Precision: Automated cranes use sensors and control systems to perform tasks with high accuracy, reducing the risk of human error.

- Speed and Efficiency: Automated cranes are typically faster and more efficient because they can work continuously and perform tasks with minimal delay.

- Safety: With fewer human operators involved, automated cranes reduce the risk of accidents caused by fatigue or mistakes.

Key Components of Automated Crane Systems

Automated cranes rely on a set of key components that work together to enable autonomous operation. Each part plays an essential role in ensuring the crane performs safely and efficiently.

PLCs (Programmable Logic Controllers)

PLCs are the "brains" of the crane. They process the data collected by sensors and execute pre-programmed commands. PLCs allow the crane to make real-time decisions and ensure the smooth execution of tasks, such as lifting, lowering, or moving a load.

- Purpose: Interpret sensor data and direct crane operations, ensuring the crane follows safety protocols and operates efficiently.

Sensors

Sensors are used throughout the crane system to monitor and collect data on various aspects of the crane's environment. These include load weights, nearby obstacles, and the position of the crane and its load. The sensors help the crane make informed decisions, ensuring safe and accurate operation.

- Types: Proximity sensors, load sensors, vision sensors (e.g., cameras or lasers)

- Purpose: Provide real-time feedback to the system, helping to detect issues like obstacles or overloading.

Automated Control Systems

These systems handle the actual operation of the crane. They send commands to the motors, brakes, and other mechanical components to carry out lifting and movement tasks. The control system takes the processed data from the PLCs and adjusts the crane's actions accordingly.

- Purpose: Ensure the crane performs tasks smoothly and efficiently by coordinating all mechanical functions.

Smart Systems

Smart systems add an extra layer of intelligence to the crane by using AI and machine learning technologies. These systems allow the crane to learn from its past operations and continuously improve its performance. They can also provide real-time monitoring and predictive maintenance, helping to reduce downtime and extend the life of the crane.

- Purpose: Optimize performance, predict maintenance needs, and improve decision-making by using advanced algorithms and real-time data analysis.

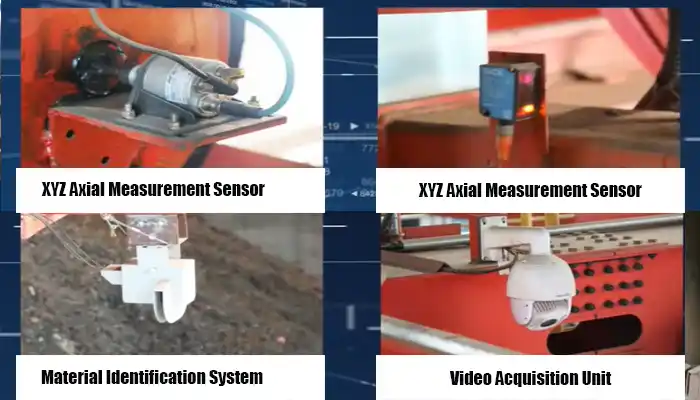

axial measurement sensor, material handling identifiation system, and video acquisition unit

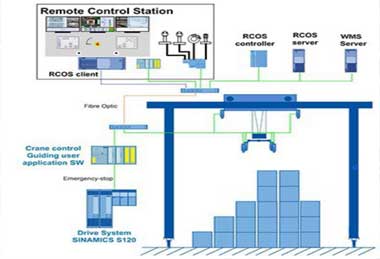

remote communication network, wireless receiver, smart edge secrurity protector, operator console prcessor

Automated crane systems are a blend of sensors, advanced control systems, and smart technology. These components work together to allow the crane to operate autonomously, offering increased safety, precision, and efficiency compared to traditional manual cranes. Whether semi-automated or fully automated, these cranes are built to enhance performance and reduce the need for human involvement.

Your Trusted Overhead Crane Manufacturer & Supplier

Types of Automated Cranes

Automated cranes come in different types to suit the specific needs of various industries. Each type uses advanced technologies to improve efficiency, safety, and precision in handling materials. Below, we'll focus on automated overhead cranes and explore their features, ideal applications, and some specialized types used in different sectors.

Automated Overhead Cranes

Automated overhead cranes are essential for industries that require precise handling of materials across large indoor spaces. These cranes run along tracks mounted on the ceiling and can lift, move, and position heavy loads with minimal human intervention. They are widely used in environments like steel mills, warehouses, and manufacturing plants, where efficiency and safety are critical.

Key Features:

- Autonomous Operation: Automated overhead cranes are capable of operating independently with minimal human involvement. They follow pre-set instructions for lifting, moving, and positioning loads.

- Integration with Warehouse Management Systems (WMS): Many automated overhead cranes are linked to WMS or Material Handling Systems (MHS) for better control and tracking of inventory and material movement.

- Precision and Safety: Advanced sensors and real-time monitoring ensure that these cranes operate with high accuracy, reducing risks and enhancing safety.

- Energy Efficiency: These cranes are often designed to reduce energy consumption, especially in high-frequency applications like warehouses or production lines.

Ideal Applications: Automated overhead cranes are widely used across various industries. They are particularly useful in environments where high precision, fast material handling, and safety are essential.

- Steel Mills: They are used to move steel products such as billets, coils, and beams, improving production flow and minimizing downtime.

- Warehouses: In warehouses, they automate the process of moving goods, helping with faster loading/unloading and better inventory management.

- Manufacturing Plants: These cranes are ideal for lifting heavy materials or parts within production lines, reducing manual labor and improving overall efficiency.

Types of Automatic 0verhead Cranes offering

From overhead crane, bridge cranes, transfer carts, and 2-ton stacker cranes to garbage handling cranes, we provide a comprehensive selection of automated material handling equipment. Whatever sort of automation you select, your crane equipment must be capable of handling any application or load size. Here are some samples of the automated cranes and services we offer:

We not only provide world-class overhead crane equipment, but our knowledgeable experts can also assist with the whole installation of each application.

We provide a variety of automatic cranes that can be utilized in a variety of industrial applications. We also provided semi-automatic cranes, which can be operated both automatically and manually. With the automatic crane systems, the repeated material handling works can be operated by the overhead cranes once the crane operator has made the settings accordingly. Automatic cranes are extensively employed in hazardous areas because of this functionality. The automated cranes will significantly decrease labor expenses, reduce damage, and boost productivity.

Intelligent Electromagnetic Crane

This type of crane is designed to handle ferrous materials using electromagnetic lifting systems. It's commonly used in steel mills and scrap yards where ferrous materials like steel need to be lifted and moved.

- Applications: Steel mills, metal recycling plants, and warehouses handling metal products.

- Benefits: Efficient handling of metal loads with reduced human labor, minimizing material damage.

Intelligent Bulk Material Handling Crane

Used for moving bulk materials such as coal, sand, and cement, this crane is equipped with specialized attachments like buckets or clamshells for lifting loose materials.

- Applications: Cement plants, mining industries, and bulk storage facilities.

- Benefits: Reduces manual labor, speeds up bulk material handling, and increases safety.

Steel Coil Storage Intelligent Logistics System

This crane system is designed to automate the handling and storage of steel coils. It integrates intelligent software to track coil sizes and weights, optimizing storage and retrieval.

- Applications: Steel mills, particularly in coil storage areas.

- Benefits: Optimizes storage space, improves organization, and reduces coil damage during storage.

Cold Rolling Shop Smart Logistics

These automated cranes are used in cold rolling shops to move steel sheets between stages of the rolling process. They are integrated with sensors to ensure precision and minimize manual handling.

- Applications: Cold rolling mills for steel processing.

- Benefits: Increases production efficiency, reduces material handling errors, and improves safety by limiting human interaction with heavy equipment.

Automated overhead cranes are versatile machines that bring enhanced operational efficiency, safety, and precision to industries like steel production, logistics, and manufacturing. By utilizing advanced technology, these cranes help businesses streamline their operations and reduce reliance on manual labor.

Crane Automation of Industrial Overhead Crane

Automation of overhead cranes. Your overhead crane system is unquestionably vital to the daily operation of your company while handling even the most massive loads. Consider how much more efficient this procedure could be.

Not only may automating your crane system save your overall production costs, but it can also improve your facility's safety and productivity.We can work with you to design an unique crane system that meets even the most stringent lifting requirements.

Our in-house engineers collaborate with you to design a semi-automatic or completely automated system that can incorporate bridge cranes, transfer carts, and other equipment.

Semi-automated & Fully-automated crane system

Based on your specific requirements, we design semi-automated or fully automated crane systems. Various features are offered in a semi-automated system to help the crane operator while yet retaining some manual control.

On the other hand, with a completely automated system, the user can make the settings and the computer will take care of the rest. This is especially effective in high-stress or dangerous situations. Operators are spared the fatigue of very repeated or demanding handling activities with these types of equipment. Users don't have to deal with the monotony of duty cycles and repetitive lifting, placing, stacking, and storing because these activities are managed mechanically; as a result, they will make less mistakes, which improves total manufacturing accuracy.

Benefits of Automated Overhead Cranes

- Within a single computer program, an automated crane system can control an entire intralogistics system. An automated system, manned by an operator in a control room rather than a crane cab, can help reduce the risk of worker injury while maintaining the same level of efficiency and precision. Along with increased safety, accuracy, and efficiency, automating your overhead crane system can provide a variety of other competitive advantages, such as:

- Handle heavy loads with ease.

- Reduce operating costs by employing fewer people and streamlining operations.

- Increase productivity by improving the efficiency and effectiveness of work.

- Improve workplace safety by incorporating crane automation systems, especially when working in hazardous areas or with hazardous materials.

- Reduce the amount of damage caused by handling objects.

- Inventory tracking capability, optimized storage space and inventory management, and the ability to configure the movements to be performed

- Less maintenance, less downtime

All industries, including plating, aluminum, aluminum extrusion, steel production, steel warehousing, and others, can benefit from an overhead crane system to streamline general manufacturing.

Automated Gantry Cranes

Automated gantry cranes are widely used for lifting and transporting heavy loads across large outdoor spaces. They are particularly well-suited for environments like shipyards, container yards, and construction sites where heavy and bulky materials need to be moved efficiently. These cranes use automation technology to operate with little or no human involvement, improving speed, safety, and precision.

Use in Shipyards, Container Yards, and Construction Sites

Automated gantry cranes are especially valuable in industries like shipping, construction, and logistics. They are designed to handle large, heavy items such as containers, steel beams, or heavy machinery. Here's why they're essential:

- Shipyards: In shipyards, automated gantry cranes are crucial for lifting heavy ship parts, containers, and equipment. They help with the construction, maintenance, and repair of vessels, improving efficiency and safety.

- Container Yards: In container terminals, automated gantry cranes are used to move shipping containers from one location to another. They are typically paired with automated container stacking systems for faster and more efficient handling.

- Construction Sites: These cranes can be used to transport heavy construction materials like steel beams, prefabricated parts, and concrete blocks, reducing manual labor and improving project timelines.

The key advantages of automated gantry cranes in these environments are their ability to handle large volumes of material quickly, with high precision, and without the risk of human error.

Types of Automated Gantry Cranes

There are two main types of automated gantry cranes commonly used in industrial applications: Rubber Tyred Gantry (RTG) cranes and Rail-Mounted Gantry (RMG) cranes. Both types are designed for specific operational needs and environments, each with its own set of benefits.

Automated Rubber Tyred Gantry (RTG) Cranes

Features: RTG cranes are mobile cranes that run on rubber tyres instead of rails, making them ideal for container yards and port terminals where flexibility and mobility are essential. They can move containers and other materials across large outdoor areas, and their tires allow for easier movement between different sections of the yard.

Applications: Commonly used in container yards, ports, and logistics hubs where containers need to be stacked and transported across large spaces.

Benefits:

- Flexible and mobile, allowing them to move freely within the yard.

- Suitable for outdoor environments with less infrastructure for rails.

- Capable of stacking containers high and handling a variety of cargo types.

Automated Rail-Mounted Gantry (RMG) Cranes

Features: RMG cranes, unlike RTGs, run along fixed rail tracks and are typically used for more structured and high-density environments like ports. These cranes are excellent for heavy-duty operations, handling large volumes of containers in a fixed space with high precision.

Applications: Primarily used in container terminals, intermodal yards, and ports for stacking and moving containers.

Benefits:

- Higher load capacity and lifting height, ideal for stacking containers in tight spaces.

- Operates in a defined area, which improves space optimization.

- Highly efficient in managing large-scale container operations.

Why Use Automated Gantry Cranes?

- Enhanced Efficiency: Automated gantry cranes can operate continuously, making them perfect for high-volume environments like ports, where time is critical. They reduce the need for manual labor, speeding up material handling.

- Precision and Safety: Equipped with advanced sensors, these cranes can operate with high precision, minimizing the risk of accidents or damage to cargo. Real-time data allows for continuous monitoring, ensuring safe operation.

- Cost Savings: By reducing human labor and improving operational speed, automated gantry cranes can lead to significant cost savings in the long run.

Automated gantry cranes are essential in industries that require heavy lifting and transportation over large areas. Whether it's a Rubber Tyred Gantry (RTG) or a Rail-Mounted Gantry (RMG) crane, each type offers distinct advantages depending on the environment and needs. With their ability to handle large volumes efficiently and safely, these cranes are transforming operations in ports, container yards, and construction sites worldwide.

Automated Container Cranes

Automated container cranes are critical to the smooth operation of ports and terminals where containerized cargo is the primary method of transportation. These cranes are designed to load and unload containers from ships, transport them within the port, and place them in storage or on trucks for further distribution. With the rapid growth in global trade, the demand for automation in port operations has surged to improve efficiency, safety, and throughput.

High-Efficiency Cargo Handling at Ports

Automated container cranes are essential for managing the high volumes of containerized goods that pass through ports worldwide. They are designed to operate with minimal human intervention, significantly speeding up the container handling process while reducing operational costs. These cranes are equipped with advanced sensors, cameras, and real-time data integration to ensure the precise and safe movement of containers.

Key advantages of automated container cranes include:

- Faster Turnaround Time: Automated container cranes can work continuously without breaks, significantly reducing the time it takes to load or unload a vessel. This leads to quicker turnaround times for ships, improving the port's throughput capacity.

- Increased Precision: These cranes are equipped with advanced navigation systems that ensure accurate placement of containers, reducing the risk of errors or damage to cargo.

- Safety: With fewer human workers in potentially hazardous areas, automated container cranes improve safety by eliminating the risk of accidents associated with manual operations.

- 24/7 Operation: Automated systems can operate around the clock, boosting productivity and ensuring that container handling continues without disruption, even during nighttime or in adverse weather conditions.

Key Features of Automated Container Cranes:

- Remote Control and Autonomous Operation: Automated container cranes are typically operated remotely, often from a control room that oversees multiple cranes. Some systems even operate fully autonomously, utilizing artificial intelligence (AI) to optimize container movement without human intervention.

- Advanced Sensor Technology: These cranes use sensors to detect obstacles, monitor the position of containers, and ensure that they are securely lifted and moved. This technology improves both safety and efficiency.

- Integration with Port Management Systems: Automated container cranes are usually integrated with the port's management system, allowing for seamless coordination between the cranes, trucks, and storage areas. This ensures that containers are transported efficiently and accurately throughout the port.

- High-Speed Lifting and Moving: These cranes are built for high-speed operation, capable of lifting and moving containers swiftly, increasing the port's overall capacity to handle large volumes of cargo.

Types of Automated Container Cranes

Automated Ship-to-Shore (STS) Cranes

These cranes are designed to load and unload containers from vessels at the dock. They are typically mounted on rails along the quay and can reach over the sides of large container ships. Automated STS cranes are often the most visible type of container crane in a port terminal.

- Applications: Used to unload containers from large ocean-going vessels and load them onto trucks, trains, or storage areas.

- Benefits: High lifting capacity, rapid loading/unloading speeds, and high-precision handling.

Automated Rail-Mounted Gantry (RMG) Cranes

RMG cranes are used to move containers across the port once they are unloaded from ships. They run on fixed rails and are typically used for stacking containers in the yard or transferring them to trucks and railcars.

- Applications: Used to stack containers in the yard, transfer containers to/from storage areas, or load/unload containers from trucks and trains.

- Benefits: Efficient container stacking and retrieval, high precision, and reduced labor costs in the yard.

Automated Rubber-Tyred Gantry (RTG) Cranes

RTG cranes are mobile, running on rubber tires rather than rails, and can move freely within the container yard. They are ideal for container terminals where flexibility and mobility are required.

- Applications: Used for stacking containers in outdoor yards, handling containers in areas with fewer infrastructure requirements.

- Benefits: Flexibility to move between different sections of the yard and the ability to operate in diverse conditions.

Why Use Automated Container Cranes?

- Improved Port Efficiency: Automated container cranes allow ports to handle higher volumes of cargo in less time, significantly reducing congestion and improving port throughput.

- Cost Savings: Although the initial investment in automated container cranes can be high, the long-term savings from reduced labor costs, fewer accidents, and higher operational efficiency make these systems cost-effective.

- Environmental Benefits: Automated systems tend to be more energy-efficient and environmentally friendly. Many automated cranes are designed to operate with optimized energy usage, reducing fuel consumption and emissions.

- Scalability: Automated container cranes can easily be scaled to meet growing port demands. They can handle increasing cargo volumes without the need for significant additional infrastructure.

Automated container cranes are transforming the way ports handle shipping containers, offering significant improvements in speed, accuracy, and safety. By integrating advanced technologies such as AI, real-time data tracking, and autonomous systems, these cranes provide ports with the tools needed to stay competitive in the fast-paced world of global shipping.

Smart Features Enhancing Automated Cranes

As automation continues to reshape the crane industry, the integration of smart technologies has become a game-changer. Smart features in cranes go beyond just automation—they improve efficiency, safety, and operational insights. These features allow cranes to "think" and adapt, making them more reliable and capable of handling complex tasks without the need for constant human intervention.

What Makes a Crane "Smart"?

A "smart" crane is equipped with advanced technologies that enable it to operate autonomously, communicate with other machines, and monitor its own health. Smart cranes are not just automated—they are enhanced with sensors, software, and connectivity that allow for real-time data exchange and decision-making. The ability to gather and process information from the crane and the environment allows these systems to make real-time adjustments and improvements to their operation.

Some key characteristics that define a smart crane include:

- Self-Diagnostics: Smart cranes can monitor their own performance and alert operators to potential issues before they become major problems.

- Data-Driven Decisions: These cranes use collected data to adjust operation settings such as speed, lifting capacity, and positioning for optimal performance.

- Communication: They can communicate with other equipment, systems, and operators, providing updates on load status, maintenance needs, or operational changes.

Integration with AI and IoT Technologies

Artificial Intelligence (AI) and the Internet of Things (IoT) are transforming how cranes interact with their environment and make decisions. These technologies enable cranes to become more intelligent, responsive, and efficient.

- AI (Artificial Intelligence): AI enhances the decision-making capabilities of cranes. For instance, AI algorithms can analyze data from sensors, cameras, and load monitoring systems to adjust lifting speeds, load distribution, and positioning in real-time. This allows cranes to perform tasks more efficiently and safely, while also adapting to changing conditions.

- IoT (Internet of Things): IoT enables cranes to connect to a network, allowing them to exchange data with other machines, operators, and even the central management system. This connectivity ensures that cranes can share important data, such as load weight, temperature, and operating conditions, to improve coordination and resource allocation across a facility.

For example, in a port setting, an automated container crane equipped with AI and IoT could communicate with the terminal's central system to adjust its operations based on the movement of other cranes and the arrival of new ships.

Real-Time Monitoring and Predictive Maintenance

Real-time monitoring and predictive maintenance are among the most valuable features of smart cranes. These technologies enable cranes to be monitored continuously for performance, ensuring they operate at peak efficiency and reducing the risk of unexpected failures.

- Real-Time Monitoring: Sensors placed on various crane components (such as the hoisting mechanism, motors, and control systems) provide constant updates about the crane's operational status. This allows operators to monitor performance remotely, adjust settings as needed, and address any issues before they become critical.

- Predictive Maintenance: By analyzing historical data and current conditions, predictive maintenance algorithms can forecast when a part or system is likely to fail. This enables crane operators to perform maintenance tasks before a failure occurs, reducing downtime and increasing overall operational efficiency. Predictive maintenance also helps in extending the life of the crane by preventing costly repairs and parts replacements.

In addition, predictive maintenance can help identify patterns in crane usage that may lead to wear and tear, giving companies insights into how to optimize their crane operations for maximum lifespan and minimal maintenance costs.

Why Are These Smart Features Important?

- Increased Efficiency: Smart cranes adjust automatically to changing conditions, ensuring optimal performance and minimizing energy waste. This leads to faster and more precise operations, boosting overall productivity.

- Reduced Downtime: With real-time monitoring and predictive maintenance, smart cranes experience less unexpected downtime, reducing operational disruptions.

- Cost Savings: By improving efficiency, reducing manual labor, and preventing costly repairs, smart cranes can deliver long-term cost savings for companies.

- Improved Safety: Smart features like real-time data analysis, automatic load adjustments, and safety sensors help reduce human errors and enhance overall safety in crane operations.

Smart cranes are paving the way for more efficient, reliable, and safe crane operations. By integrating advanced AI, IoT, real-time monitoring, and predictive maintenance, these cranes can enhance the capabilities of automated systems, providing greater control and performance across industries.

Intelligent Crane Technologies

Intelligent crane technologies are rapidly revolutionizing how cranes operate. By integrating AI and machine learning, these technologies enhance the crane's ability to adapt to different conditions, optimize performance, and make real-time decisions. The result is a more efficient, safer, and cost-effective operation.

Role of AI and Machine Learning in Crane Operations

Artificial Intelligence (AI) and Machine Learning (ML) are powerful tools that help cranes perform tasks more autonomously and intelligently. These technologies allow cranes to learn from past experiences and continuously improve their operations.

- AI in Crane Operations: AI allows cranes to make decisions based on data and adjust their performance accordingly. For instance, AI algorithms can process data from various sensors, cameras, and load monitoring systems to optimize speed, lift capacity, and positioning in real-time. This enables cranes to adapt quickly to varying conditions like load size, environment, and operational changes, leading to smoother, more efficient performance.

- Machine Learning in Crane Operations: Machine learning takes AI a step further by enabling cranes to learn from data patterns and improve over time. The more a crane operates, the more data it gathers about its performance and environmental factors. This allows it to adjust its operations without needing reprogramming, ensuring that the crane becomes better at handling complex or unforeseen situations.

In practice, AI and machine learning help cranes adjust their lifting techniques based on factors like load weight, wind conditions, and the crane's operational history, leading to optimized performance.

Introduction to "Intelligent Crane" and "AI Crane" Concepts

An "intelligent crane" is a crane equipped with advanced systems that allow it to not only follow preset commands but also make decisions and adapt in real time based on its environment. These systems typically integrate AI and machine learning with sensors, cameras, and data analytics to optimize the crane's functionality.

- AI Crane: The term "AI crane" refers to cranes that utilize AI algorithms to optimize their operations and ensure the most efficient, safe, and cost-effective performance. These cranes can analyze their environment, recognize obstacles, and adjust their lifting and movement strategies accordingly. AI cranes are designed to perform complex tasks autonomously, reducing the need for human intervention.

- Intelligent Crane: An intelligent crane takes the concept of an AI crane even further. It is equipped with advanced technologies like IoT connectivity, real-time monitoring, and predictive maintenance, making it capable of monitoring its health, predicting failures, and adjusting its operations autonomously. Intelligent cranes are also capable of communicating with other machines and systems in the facility, creating a fully connected and coordinated environment.

How Intelligent Systems Improve Decision-Making and Reduce Risks

Intelligent crane systems drastically improve decision-making by enabling cranes to make adjustments in real time. Here's how they reduce risks and enhance operations:

- Real-Time Adjustments: Intelligent cranes can respond to dynamic factors such as load changes, environmental conditions, or machine performance in real time. For example, if a crane is lifting a heavy load in windy conditions, the system can automatically reduce lifting speed or adjust positioning to prevent accidents or inefficiencies.

- Reduced Human Error: With intelligent systems, many tasks that traditionally required human judgment are automated. This minimizes human error, which is a significant risk in crane operations. The system can ensure that the crane operates within its safe parameters, making it safer for both workers and the crane itself.

- Improved Load Handling: Intelligent systems can calculate the best approach for lifting, transporting, and positioning loads, ensuring that the crane operates at optimal efficiency and reduces the risk of damaging loads or the crane structure.

- Predictive Maintenance and Risk Reduction: By integrating sensors and IoT technologies, intelligent cranes continuously monitor their own health. These systems can predict when components are likely to fail and suggest maintenance before a breakdown occurs, reducing downtime and preventing costly repairs or accidents. Predictive maintenance ensures that the crane operates in peak condition, reducing the likelihood of operational hazards.

- Increased Safety: With advanced AI algorithms, intelligent cranes can detect obstacles in their path, adjust their movements, and avoid collisions. This improves safety by reducing the risk of accidents, whether from improper load handling, obstacles, or worker proximity.

By incorporating AI, machine learning, and advanced sensor technologies, intelligent cranes offer significant improvements in operational efficiency, safety, and decision-making. These technologies are transforming the crane industry, making it possible to run cranes with fewer risks and higher productivity while reducing operational costs.

Your Trusted Overhead Crane Manufacturer & Supplier

Typical Applications for Automatic Cranes

There are two types of automatic cranes that we manufacture and supply. Various features help the crane operation in the semi-automatic, but greater manual control is available. With a fully automated crane, the operator sets the requirements, and the crane handles the repetitious or tough tasks automatically. This is especially effective in high-stress or dangerous situations.

Crane system automation provides a wide range of extra control factors to improve production, safety, and precision in the workplace, regardless of industrial selectors. Steel coil and paper roll handling, waste-to-energy, shipbuilding, container handling, food production, metals processing, and general manufacturing, Assembly line product handling, Dip tank operations, Sheet steel handling, Palletizing operations, and so on are all common applications for automatic cranes.

Some of the most common applications include:

- Product handling and inventory management in the factory

- Maintenance and assembly of aircraft

- Rolling and processing of paper

- Handling of high-volume container freight

- Handling in the die and machine shop

- steel coils,

- containers

- Shipbuilding

- Heavy construction

- Mechanical workshops

- Food production

- For lifting all kinds of loads

Fully automated crane systems, on the other hand, can use a single computer software to control an entire intralogistics system. These overhead cranes systems can be built to integrate production, storage, and shipping systems through every move, from load pickup to deposit sequences, for applications such as load management, storage, or die changing.

Automation in a Steel Plant

One way to incorporate safety into a steel manufacturing operation is through automation. Thanks to the convergence of information systems and operational technologies, automation in a steel mill can provide accurate positioning capabilities, repetitive motion, and built-in safety features to reduce operator injury and equipment damage. Industrial automation can improve system analysis and diagnostics in steel plants, making maintenance, troubleshooting, and operation more efficient.

The ability of automated crane systems to learn is another important feature. Advanced automated systems allow you to learn from technology by logging events such as starts, stops, and errors, among other things. This allows you to understand not only where the crane system could be improved, but also how the operators use it. Operators, managers, and trainers can use the data to identify potential training opportunities to improve safety and efficiency. Read moe on Steel Mill Automation.

Automatic Overhead Cane for Steel Processing

Material handling equipment is required in scrap yards, steel mills, rolling mills, and electrolytic metallurgical operations. The most important factor is reliability, because any unplanned downtime will result in scrap and lower output.

In steel plants, charge cranes and ladle cranes must be able to work around furnaces and molten steel, typically at temperatures above 70°C. Overhead cranes for handling iron bars, billets, and coils are usually operated at high speeds and required to position and rotate loads precisely. Finally, common electrical components will deteriorate in the environment surrounding electrolytic metallurgy and electroplating lines.

The automatic crane and semi-automated overhead crane system are available to provide safety and efficiency during all steel production activities.

Automatic Crane for Steel Coiling Handling

You can use automated stacking crane solutions for warehouse applications to fetch pallets or components from specified places in a facility with little or no human intervention.

Automated Coiling Stacking Crane/Stock Yard Automation

Variable Frequency Drives (VFDs) are now included (VFDs). For your material handling processes, a plethora of solutions become available. VFDs can be connected to and integrated with systems that can link and control many drives at the same time. Additionally, extra control cards can be used to implement other procedures.

Automatic Crane for Automotive Industry

We provide process automatic cranes designed for specific applications in automotive press plants that are integrated into our customers' complex manufacturing processes. The overhead cranes ensure that the necessary tools are stored and delivered to the press lines in a timely manner.

In stamping plants, the use of semi-automatic clamp die handling cranes is changing the layout of automotive manufacturing. Lifting locks are installed in the four corners of modern molds, making it easier for the overhead crane to pick up molds from the mold library via the four-side-capable and load-sensing clamps. Ordinary overhead cranes require a crane operator and two people to secure the rope in order to lift the mold. However, in semi-automatic mode, we can lift the mold with just one person. The crane operator can install it on the trolley or spreader at the same time. On the wireless remote control display, the upper camera displays the current situation at the operation site in real time. More on Cranes for Automotives.

Automatic Crane for Container Handling

Standard containers are used for the majority of international trade. Sea and river port container terminals, as well as rail and road terminals, require efficient, dependable, and harsh-environment electric container handling equipment to satisfy the demands of 24/7 operation.

Container handling is handled by rail-mounted gantry cranes (RMG) and rubber-tyred gantry cranes (RTG). Larger container ships necessitate container cranes that are larger, faster, and more reliable, with a greater reliance on electrical components. Port container handling equipment is transitioning from internal combustion engines to electric drives in order to reduce fossil fuel usage and pollution.

The automatic crane for container handling has a remote control operating system.

Benefits to the user:

- Remote real-time operation

- Increase operational time by using a hot-swappable operator.

- Reduce the amount of time it takes to complete a task.

- Multiple cranes can be controlled by a single operator.

- Expand the number of repositories available to users.

Automatic Overhead Crane for Paper Roll Handling

This automated crane system not only makes it safer for your employees to work, but it also makes it easier to get raw materials into the paper and pulp manufacturing process.

Highlights:

- System for automatic overhead delivery

- A more secure working environment

- Custom-programmed to stay up with your manufacturing process

- Spent core and core plug management

- Core plugs are automatically removed.

Automatic Overhead Crane with Grab for Waste Handling

In waste processing facilities for refuse-derived fuels and cogeneration plants, an automatic overhead crane with grab for waste handling is a significant piece of equipment. For garbage charging, transport, mixing, and weighing, a waste disposal crane is erected over the garbage pit.

It can be operated manually, semi-automatically, or fully automatically, performing automatic grabbing, automatic repeat feeding, automatic repeat dumping, and automatic parking. The three modes are freely switchable, and manual control always takes precedence in any automatic mode. The automatic waste handling cranes are commonly used in waste incineration plants with daily processing capacities ranging from 600 T/D to 4800 T/D. More information, please check our automatic wastes handling cranes.

Crane Automation Solutions for Specific Needs

As industries evolve, so do the requirements for crane systems. Depending on the operational needs, cranes can be automated to different levels—ranging from semi-automated systems for light assistance to fully automated solutions that require minimal human interaction. Understanding the specific needs of your operation can help determine the best level of automation for your crane system.

Semi-Automated Crane Systems

Semi-automated crane systems are a great option for operations that need some level of automation but still require human oversight. In these systems, some tasks are automated—such as lifting, moving, or positioning loads—but the operator remains in control of critical decisions and adjustments.

When Semi-Automated Solutions Are Enough

Semi-automated crane systems work well for operations where full automation isn't necessary or when the tasks require a certain degree of flexibility. They are ideal in environments where the volume of lifting tasks is moderate or variable, and a full automation solution would not provide enough return on investment. Semi-automation allows for:

- Cost-Effective Operations: Semi-automated systems are less expensive to implement compared to fully automated solutions. They offer a good balance between automation and manual control, reducing labor costs without requiring a complete overhaul of the system.

- Improved Efficiency: Semi-automation reduces the physical demands on workers and speeds up certain tasks (like load lifting and transportation), while still allowing the operator to intervene when needed.

- Control Flexibility: In semi-automated systems, operators have more control, which can be important for handling complex or variable tasks that require human judgment or oversight.

- Easier Implementation: Semi-automated systems are easier and quicker to implement in existing facilities, making them a good option for operations that don't want to undergo a major technological overhaul.

This system works especially well for environments like warehouses or light industrial facilities where automation can assist with repetitive tasks but flexibility is still necessary.

Full Automation: End-to-End Control

Full automation takes crane operations to the next level by enabling continuous, unmanned control. These systems are ideal for high-volume, repetitive tasks where human intervention is not required for regular operations. In fully automated systems, the crane operates autonomously, from start to finish, without human oversight.

Fully Automated Crane Systems for Continuous, Unmanned Operations

Fully automated cranes are suited for environments where efficiency, speed, and precision are paramount, and where human presence may not be necessary or even desired.

- 24/7 Operations: Full automation enables cranes to operate around the clock, without the need for breaks or shifts. This is particularly useful in high-demand industries like ports, manufacturing, and warehouses, where continuous, efficient operations are critical.

- Increased Efficiency and Speed: Fully automated systems can perform tasks faster and with fewer errors. Since these systems do not rely on human judgment, they can consistently handle tasks like loading, unloading, and stacking with high precision, increasing throughput.

- Lower Labor Costs: With no need for operators to be physically present, full automation dramatically reduces labor costs. This is a major benefit in industries like shipping or manufacturing, where labor expenses can be significant.

- Safety and Risk Reduction: In hazardous environments or areas where heavy lifting is required, fully automated cranes can help keep human workers out of harm's way. By removing the need for direct human involvement, these systems help mitigate safety risks associated with lifting heavy loads or working in dangerous conditions.

- Predictive Maintenance and Remote Monitoring: Fully automated cranes are typically integrated with predictive maintenance systems, allowing for real-time monitoring and early detection of potential issues. This ensures maximum uptime and reduces unexpected failures, making operations smoother.

Fully automated systems are ideal for high-traffic environments like ports or large distribution centers, where efficiency and speed are vital, and the repetitive nature of the work makes human oversight unnecessary.

Advanced Crane Systems and Services

As industries continue to push for more efficient and powerful lifting solutions, advanced crane systems are designed to meet the demands of high-performance lifting. These systems integrate cutting-edge technologies to improve safety, precision, and speed, offering customized solutions tailored to specific lifting needs. Whether it's a unique load requirement or the need for specialized crane rigging, advanced crane services provide the flexibility and efficiency to handle complex tasks.

Advanced Technologies for High-Performance Lifting

Advanced crane systems are equipped with state-of-the-art technologies to ensure superior performance in demanding environments. These systems are designed for precision, reliability, and speed, making them ideal for industries that require heavy lifting and complex operations.

- Precision Lifting: With advanced control systems, modern cranes are able to perform precise movements, even with heavy or oversized loads. These systems allow for micro-adjustments in positioning, ensuring that loads are placed exactly where they are needed with minimal risk of damage.

- High Load Capacity: Advanced cranes are built to handle heavier loads with greater ease. They use robust hoisting mechanisms, stronger materials, and more powerful motors to lift and move large, heavy objects safely and efficiently.

- Increased Speed: Newer crane technologies can move loads faster without sacrificing safety or control. Automation and advanced controls allow cranes to operate at optimal speeds, significantly reducing cycle times and increasing overall productivity.

- Enhanced Safety Features: Modern crane systems are equipped with a variety of safety features like overload protection, automatic load monitoring, and anti-collision systems. These systems ensure the safety of workers and equipment, preventing accidents and ensuring that lifting operations are carried out within safe parameters.

Customized Automation and Crane Rigging Solutions

Every industrial lifting project has unique requirements, and advanced crane systems offer tailored solutions to meet these needs. Whether it's for a specific load, environment, or operational condition, customized crane automation and rigging solutions ensure that operations are as efficient and safe as possible.

- Tailored Automation Solutions: Automation can be customized to match the specific needs of your operations. This includes the ability to adjust lifting speeds, load tracking, and even remote control options to optimize performance in particular environments like steel mills, warehouses, or ports.

- Specialized Crane Rigging: Rigging solutions are critical for safely lifting and moving heavy or irregularly shaped loads. Advanced crane rigging services can provide customized lifting setups that ensure load stability and safety. This includes using specialized hooks, slings, and lifting beams designed for specific load types.

- Optimized Workflow Integration: Advanced crane systems are often integrated with other industrial processes, such as assembly lines or warehouse management systems. Custom solutions can be designed to fit seamlessly into these operations, improving overall workflow efficiency and reducing downtime.

- Flexible Systems: Advanced crane systems can be designed to adapt to changing needs, whether it's a seasonal increase in load capacity or a shift in operational requirements. This flexibility allows businesses to scale up or adjust their crane systems without the need for a complete overhaul.

Choosing the Right Automated Crane System

Selecting the right automated crane system is a critical decision that impacts efficiency, safety, and cost-effectiveness in operations. Several key factors must be considered to ensure that the chosen system aligns with your specific needs and goals. Understanding these factors will help you make an informed decision about which type of crane system—smart, automated, intelligent, or advanced—will best meet your operational requirements.

Factors to Consider

When choosing an automated crane system, consider the following factors to ensure that it fits well with your operational goals and environment.

Application and Environment (Indoor vs. Outdoor)

The environment in which your crane will operate is one of the most important considerations when selecting an automated system.

- Indoor Cranes: Cranes used indoors typically face different challenges than outdoor cranes. For example, space constraints, ceiling height, and load movement within confined spaces need to be considered. Automated systems for indoor use may also be designed for smoother, quieter operations and finer control.

- Outdoor Cranes: Outdoor cranes need to be designed to withstand varying weather conditions like rain, snow, and high winds. Systems for outdoor use may require additional protective features, such as weatherproofing and corrosion-resistant materials. Additionally, outdoor cranes may need to handle larger loads over greater distances, requiring more robust lifting systems.

Load Requirements

The type and weight of the loads that the crane needs to lift will significantly impact your choice.

- Light to Moderate Loads: If the crane will handle lighter loads, a semi-automated or fully automated crane system might suffice, without the need for excessive lifting power or advanced systems.

- Heavy or Over-Sized Loads: If you're lifting heavy, bulky, or irregularly shaped loads, you'll need a crane with a higher load capacity. A fully automated system with advanced sensors and control mechanisms might be necessary for precision and safety when handling these heavy loads.

Span and Lifting Height

The span (horizontal distance) and lifting height (vertical distance) are also key factors in determining the right system for your needs.

- Span Considerations: The horizontal reach of the crane must be suitable for the area where you intend to operate. A system designed to cover a large span may require more robust structures and a higher capacity to ensure smooth operation over long distances.

- Lifting Height: Depending on the height at which loads need to be moved, cranes are built with different lifting capacities. Automated cranes with high lifting requirements often include specialized hoists, reinforced structures, and additional safety mechanisms to ensure safe operation at elevated heights.

Desired Level of Automation

Understanding how much automation is needed is critical in selecting the right crane system. Automation levels range from simple assistance with basic controls to fully autonomous operation.

- Semi-Automated: If your operations require a combination of automation and manual control, a semi-automated crane system will be ideal. This system can provide efficiencies but still allows the operator to intervene when necessary.

- Fully Automated: If you're looking for a system that operates independently without human oversight, a fully automated crane system may be the best option. This system would be ideal for high-volume, repetitive tasks where safety and speed are critical, such as in ports or large warehouses.

How to Select Between Smart, Automated, Intelligent, and Advanced Crane Solutions

Understanding the differences between smart, automated, intelligent, and advanced cranes will help you choose the best solution for your specific needs.

- Smart Cranes: Smart cranes are equipped with sensors and IoT technology to provide real-time data and feedback. They enable predictive maintenance, optimize load handling, and improve operational visibility. If you want enhanced monitoring and decision-making capabilities, a smart crane might be the best choice.

- Automated Cranes: These cranes are programmed to perform certain tasks automatically with minimal human intervention. They are ideal for applications where tasks are repetitive and can be standardized, such as in large warehouses or assembly lines. If you need a system that can improve speed and reduce human error, an automated crane is a good fit.

- Intelligent Cranes: Intelligent cranes use advanced AI and machine learning technologies to make real-time decisions based on the data they collect. These systems can adapt to changing conditions and optimize operations without manual intervention. If you're looking for a crane that can learn and adjust to varying conditions on the fly, an intelligent crane would be the best choice.

- Advanced Crane Systems: Advanced crane systems integrate customized solutions, cutting-edge technologies, and high-performance components to meet the specific demands of complex or heavy-duty tasks. If your application involves high-performance lifting or requires specialized solutions, such as in steel mills or heavy construction sites, an advanced crane system will provide the precision and reliability you need.

By carefully considering your application's specific needs—such as load requirements, span, height, automation level, and desired technological capabilities—you can select the crane system that will deliver the best performance, efficiency, and value for your operations.

Case Studies

Automated crane systems are transforming industries by improving efficiency, reducing labor costs, and increasing safety. Below are a few examples of how these systems are being applied across various sectors.

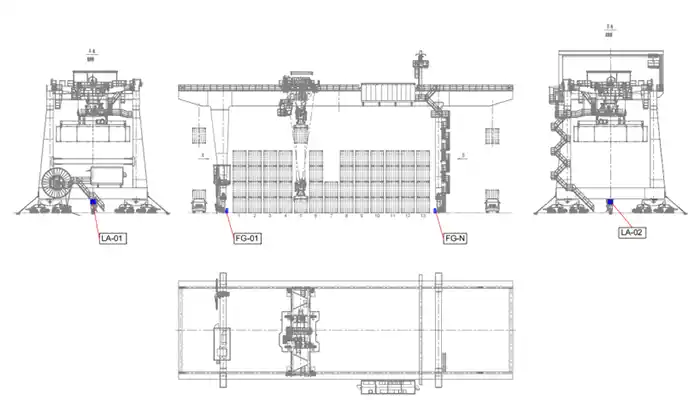

Ramounted gantry crane for container handling

drawing of automatic rail mounted gantry crane for container handling

Port Container Handling: Automated Gantry Cranes

Automated gantry cranes (AGCs) are revolutionizing port operations by improving the efficiency of container handling at terminals. These cranes are capable of moving large containers onto and off ships with minimal human intervention.

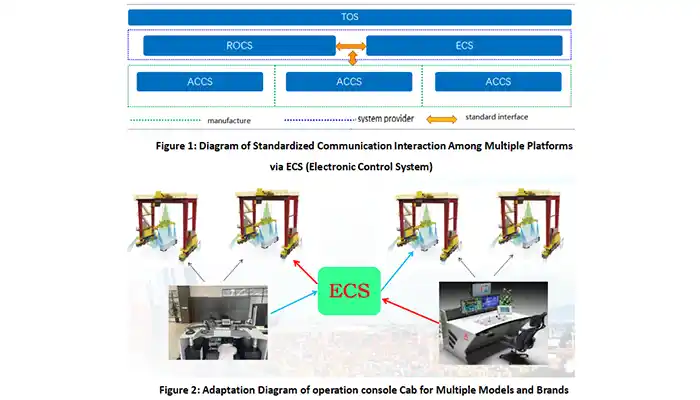

How They Work: AGCs typically operate along rails and are equipped with advanced sensors, automated control systems, and AI to perform tasks like container loading, unloading, and stacking. These cranes can work autonomously, following programmed routes and adjusting to real-time conditions.

Key Benefits:

- Higher Throughput: Automated gantry cranes can operate 24/7 without needing breaks, allowing for faster turnaround times for ships and trucks.

- Improved Safety: With minimal human involvement, the risk of accidents and injuries is reduced, especially in such high-risk environments.

- Efficiency: These cranes can operate with high precision, optimizing container movements and reducing idle time.

- Cost Savings: AGCs can lead to significant savings in labor costs and operational expenses in busy ports by reducing the need for human operators and improving crane utilization.

Real-World Case: The Port of Rotterdam in the Netherlands is using automated gantry cranes to improve container handling operations. These cranes are part of a larger, fully automated terminal that boosts the port's efficiency and sustainability.

Future Trends in Automated Cranes

The automated crane industry is rapidly evolving, driven by advancements in technology. As industries demand higher efficiency, lower costs, and greater safety, new trends are emerging to shape the future of crane systems.

Increasing Integration with 5G, AI, and Remote Operation Control Systems

As digital technology continues to evolve, automated cranes are being integrated with the latest innovations in 5G, AI, and remote control technologies. This integration will push the capabilities of cranes to new levels.

- 5G Connectivity: The adoption of 5G technology will enable faster data transmission between cranes, sensors, and control systems. This will allow for real-time data analytics, remote diagnostics, and optimized crane performance. 5G will also improve communication between cranes in a fleet, allowing for better coordination and efficiency in busy environments like ports and warehouses.

- AI and Machine Learning: Artificial Intelligence (AI) and machine learning algorithms will continue to play a significant role in crane automation. AI can optimize crane movement patterns, predict maintenance needs, and adapt to changing operational conditions, leading to smoother and more efficient operations.

- Remote Operation: Remote operation control systems will allow operators to control cranes from a distance, potentially from a central control center. This capability will not only improve safety by removing operators from hazardous environments but also enable more flexible and efficient crane management.

Evolution of Smart and Intelligent Cranes in Industry 4.0

Industry 4.0 refers to the integration of cyber-physical systems, IoT, and cloud computing to create smarter, more interconnected production environments. Automated cranes are becoming a key component of this revolution.

- Smart Cranes: These cranes are equipped with sensors and connected to IoT networks, allowing for real-time monitoring, remote diagnostics, and predictive maintenance. Smart cranes can collect vast amounts of data that can be analyzed to improve crane performance, optimize load handling, and enhance safety.

- Intelligent Cranes: Intelligent cranes take automation a step further by using AI to make decisions in real-time. For instance, an intelligent crane might adjust its lifting speed or path based on the weight of the load, environmental conditions, or even traffic patterns within a port. This ability to adapt in real-time improves the flexibility and efficiency of operations.

- Future Impact: As these technologies evolve, cranes will become more autonomous, requiring less human oversight and being able to handle more complex tasks. This will result in better productivity, less downtime, and more sustainable operations as industries move toward fully automated environments.

The future of automated cranes is bright, with continuous advancements driving greater capabilities and efficiencies in various industries, from warehouses and ports to steel mills and construction sites. As technologies like 5G, AI, and Industry 4.0 technologies continue to advance, cranes will become even more intelligent and integrated into the broader ecosystem of smart manufacturing and logistics.

Conclusion

Automated cranes have become a cornerstone of modern industrial operations, driving the next wave of innovation across various sectors. From ports and warehouses to steel mills and construction sites, these cranes are transforming the way businesses approach material handling, improving efficiency, safety, and overall productivity.

Recap of Why Automated Cranes Are Crucial for Modern Industries

As industries evolve, the demand for faster, safer, and more efficient operations has never been higher. Automated cranes play a pivotal role in meeting these needs by:

- Increasing Efficiency: With minimal downtime and the ability to operate continuously, automated cranes streamline workflows, improve throughput, and reduce operational delays.

- Enhancing Safety: By reducing human involvement in hazardous environments, automated cranes lower the risk of accidents and injuries, making workplaces safer for everyone.

- Optimizing Costs: Automated cranes can significantly cut labor costs and improve resource utilization, leading to long-term savings for businesses.

- Adapting to Industry Needs: Whether it's high-capacity steel coil handling or fast-paced container unloading, automated cranes can be tailored to fit the specific requirements of different industries.

- Supporting Industry 4.0: With integration into smart systems, AI, IoT, and real-time data analytics, automated cranes help businesses stay ahead in the digital age, adapting to new demands and optimizing operations.

Final Tips on Selecting the Right Partner for an Automated Crane Project

Choosing the right partner for your automated crane project is just as important as selecting the right system. Here are some tips to guide you through the process:

- Experience and Expertise: Look for a partner with proven experience in designing and deploying automated crane systems, especially in your specific industry. They should understand the challenges and nuances of your operations.

- Customization Capabilities: Ensure your partner can provide customized solutions that meet your unique operational needs. Whether it's for indoor warehouse operations or outdoor port handling, your partner should be able to offer tailored automation solutions.

- Support and Maintenance: Choose a partner who offers reliable after-sales support and maintenance services. Automated cranes require regular maintenance, and having a dependable service team ensures your system stays in peak condition.

- Technological Innovation: Make sure your partner is up to date with the latest technologies, such as AI integration, real-time monitoring, and 5G connectivity. The best partners will help you stay ahead of the curve in terms of automation.

- Scalability: Your automation needs may evolve over time, so it's important to select a partner who can provide scalable solutions that grow with your business, whether that means adding more cranes or expanding automation to other parts of your facility.

- Cost Considerations: While initial costs are important, don't forget to consider the long-term return on investment (ROI) automation can provide. A good partner should offer a clear breakdown of costs and highlight potential savings through improved efficiency and reduced labor costs.

In conclusion, automated cranes are indispensable in today's competitive industrial landscape. By enhancing safety, efficiency, and overall productivity, they enable businesses to stay ahead of market demands. Selecting the right partner to implement these systems is key to ensuring successful, long-term automation that meets your specific needs. So, do thorough research, ask the right questions, and choose a partner who understands your goals and can guide you every step of the way.

Customized Automatic Crane for Your Applications

The crane, as the lifeblood of your organization, keeps everything running smoothly. We want to help improve connections between all production, storage, and shipping systems, from load pickup to deposit sequence.

Since 1984, we've been a valuable partner to various industrial sectors, using overhead cranes and other overhead material handling equipment. Rather than simply being a sales outlet for automatic crane equipment, parts, repairs, and services, we take the time to consult with customers first in order to achieve the best possible results for whatever needed.

Are you ready to take your operations to the next level with automated crane solutions? Our team is here to help you design and implement a system tailored to your specific needs. Whether you're looking for a fully automated solution or a semi-automated system, we can provide you with the right crane for your industry.

Contact us today for a customized consultation and discover how we can streamline your operations with cutting-edge crane automation technology.

Automatic overhead crane case for your reference

We can design and implement automatic overhead crane solutions to increase the productivity of your material handling applications. We have the necessary project experience and years of experience for your project. To optimize your process, we will provide you with the appropriate automatic crane solution. We can provide your company with an automatic overhead crane system that has been engineered, designed, built, and installed specifically for your needs.

For speed control, an inverter was used. Provides excellent functionality, including smooth acceleration and deceleration, high-speed driving at light loads, and improved safety and work efficiency. We have also made significant advances in operational management, such as a Human-machine interface pursuing operability and automatic peripheral equipment that improves reliability.

Main parameters of the automatic overhead crane

- Automatic Crane Safety Working Load: 30t

- Automatic Crane Span: 40m

- Number of Field coil Positions: 480

Power for Main Mechanism

- Main Hoisting: 1x132 kW Unidrive SP

- Long Traveling: 2x37kW Unidrive SP

- Cross Traveling: 2x11kW Unidrive SP

- Tong: 3x2.2kW Unidrive SP

Multiple pick and load stations

- AGV Stand *1

- Pack Line Stand *1

- Paint Line Stand *4

- Cycle time: 160 seconds. Moving the coil from its resting position to the farthest diagonally opposite coil position in the coil field.

- Positioning precision: +/- 3mm

- Handling coils of varying dimensions: diameters, widths, weight, colors, etc.

- Communication: Radio Lynx with Ethernet TCP/IP: Transfer of Data from Crane Control system to Ground station

- Operation: Automation/Manual-Ground Station/Manual-local

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch